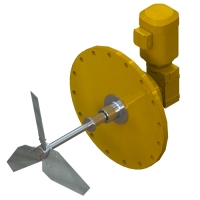

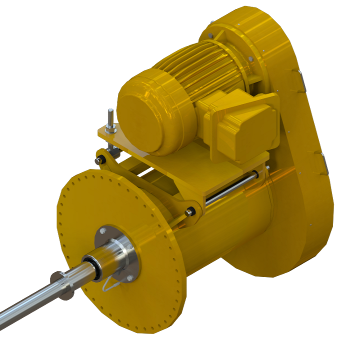

Side entry mixers suit the largest of mixing, heat transfer and solids suspension applications. These provide an efficient solution for very large applications such as reducing sludge build-up in the bottom of petrochemical storage tanks. Side Entry mixers are equipped with either a packed-gland or mechanical seal around the shaft and a shaft plug to allow seal and bearing replacement without draining the tank.

Standard Features

- Power: 20 kW ~ 200+ kW, 415v / 3Ph / 50Hz, IP56, Belt Drive

- Mixing Volume: >20’000+ L

- Shaft Length: 1m ~ 4+m

- Mounting Arrangement: Flange Mount

JM Engineering mixers can be customised to suit all mixing applications. If the options you require are not listed below, please contact us to discuss your requirements.

Download Factsheet

Drive OptionsOur standard mixers are equipped with a 415V/3Ph/50Hz motor for Australian mains power supply. To cater for all applications and environments, our power options include: –

- 415V / 3Ph / 50 Hz or International Power Specifications

- 2-Pole, 4-Pole or 8-Pole

- Flame Proof or Explosion Proof Motors

- Fixed speed or Variable Speed

- IP55, IP56 or IP66 Protection Rating

Mounting OptionsSide entry mixers are supplied in a variety of mounting options to cater for various applications. These options include:

- Flange Mount

- Base Plate Mount

Material OptionsSide Entry mixers are supplied with stainless steel wetted parts (impeller and shaft) and carbon steel mounting structures. All exposed carbon steel is coated to our painting specifications for maximum corrosion protection. Other material options include:

- Stainless Steel: 304 / 316

- Duplex Stainless Steel: SAF2205 / SAF2507

- Carbon Steel: GR250 / GR350 / 4140

- Exotic Alloys: IN-600 / Ti-2

Coating OptionsJM Engineering can provide a range of coating options for all types of mixers and impellers. This ensures a long, trouble free life in a variety of environmental conditions. Select from our standard range of coating systems, or we can supply to your own specifications. Standard options include:

- JM1 Standard Enamel– Raw surfaces blasted to AS1627 Class 2.5 and 50-60 um profile, followed by 1 coat of enamel primer and 2 enamel top coats, totalling 150 um thickness. Standard colour is AS2700 Y14 Golden Yellow.

- JM4 Standard Epoxy – Raw surfaces blasted to AS1627 Class 2.5 and 50-60 um profile, followed by 1 coat of epoxy phosphate primer and 2 recoatable polyurethane top coats, totalling 175 um thickness. Standard colour is AS2700 Y14 Golden Yellow.

- JM9 Premium Expoy – Raw surfaces blasted to AS1627 Class 2.5 and 50-60 um profile, followed by 1 coat of epoxy phosphate primer, 1 coat of surface tolerant high build epoxy and 1 coat of recoatable polyurethane top coats, totalling 250 um thickness. Standard colour is AS2700 Y14 Golden Yellow.

![]()